17 Nov Good quality HVLS ceiling fans: Four important factors to consider before making a purchase

High-flow, low-speed (HVLS) ceiling fans have become the standard for low-cost, high-efficiency climate control in many commercial and industrial applications. However, not all HVLS Fans are created equal. There are many important design and manufacturing variations that can impact everything from air movement quality, to operating and maintenance costs. When researching for a good quality HVLS fan, there are four main areas to consider, including: propeller design, hub and structural systems, safety features, and on-site consultation. All four of these factors must be properly tested to select the right HVLS fan for a particular application.

As the name suggests, HVLS fans move large amounts of air from the ceiling to the floor of the factory. This controlled airflow – ceiling to floor – creates a more comfortable and productive work environment, and helps businesses control their energy costs. Improved airflow means improved temperature control throughout the year, which ultimately saves on electricity bills. Many businesses – from distribution centers, manufacturing facilities… and farms, to shopping malls, schools, restaurants, churches… and gyms – are choosing to install HVLS fans. HVLS fans are rapidly replacing outdated high-speed fans that are noisy, less efficient, and can take up large floor space. Businesses looking to install good quality HVLS ceiling fans into their facility should understand that not all HVLS fans are created equal. There are four main factors to consider:

Nội dung bài viết

1. BLADE DESIGN OF GOOD QUALITY HVLS CEILING FANS:

The outstanding benefit of an HVLS fan is the amount of air produced, which is generated by a large diameter propeller that can extend up to 24 feet. However, the large fan diameter is only part of the design. Each propeller must be able to move air efficiently, otherwise energy will be wasted. Propeller designs vary by manufacturer, so it is important to come up with a design that produces uniform pressure and velocity from the center to the tip of the propeller. The lack of pressure and/or uneven velocity will create a number of problems, including backflow and increased energy consumption. Also, it is important to consider the angle of the blade as it relates to the plane of rotation. The overall shape and design of the blades is what generates the maximum amount of air – not the number of blades. Greentec impellers have an enhanced contoured shape that produces consistent airflow over the entire length of the blades.

2. HUB AND STRUCTURE OF GOOD QUALITY HVLS CEILING FANS:

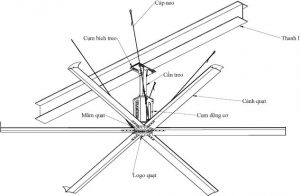

The design and construction of the propeller is very important; however, it is equally important to consider the way the propeller is mounted and the overall structure of the hub construction. A tight, solid connection between the impeller and the rim is extremely important. Similar to helicopter blades, Greentec’s propellers are attached to the rim by a load-bearing blade arm. All Greentec bladearms and balades are “rotationally balanced” at the factory and will never need adjustment. This ensures smooth and balanced operation throughout the life of the fan. Most manufacturers of HVLS fans use die castings, which are created by pouring molten aluminum into a mold. It is difficult to adjust the consistency of castings due to differences in materials and manufacturing processes. As a result, cast hubs are more porous and prone to cracking. Greentec uses a milled aluminum hub that is much more durable than a traditional die-cast hub. A computer controlled milling machine is used to remove materials from an aluminum block. This process produces a rim that is more durable and reliable when compared to a cast rim.

Structure of Greentec HVLS ceiling fan

3. SAFETY OF GOOD QUALITY HVLS CEILING FANS:

Safety is always an important factor to consider when purchasing industrial equipment. Businesses should look for HVLS fans that provide a secure connection from the motor, fan structure to installation. The fan plate is first attached to the motor using reverse threaded bolts and has a taper locking pin. Second, an anti-drop safety ring to secure the connection between the engine and the wheel. And finally, each propeller is attached to a safety ring to ensure the blades stay together as one unit. These three features work together to help ensure the safety of those under and around the fan.

4. DIRECT CONSULTATION:

Before purchasing an HVLS fan, customers should speak to an expert who can analyze a specific application. A consultant will look at things like the size and operations of the plant; the amount of open and limited space in a facility; existing HVAC systems and more. The goal is to choose the right fan size and achieve the desired airspeed with a specific floor plan. Greentec offers a wide range of good quality HVLS fans and can recommend the most suitable solution for a particular application. HVLS fans are commonly found in industrial environments such as distribution centers and manufacturing facilities, farms… however, they are becoming more common in sports facilities, theatres, churches, homes. stores, malls, and other environments where air movement is critical.

No Comments